Laser cutter is used to cut the materials to create impressive designs and patterns. This can be easily down either by trimming or cutting the material into complicated shapes that many traditional drills will find it challenging. This laser cutting technique is used by many companies to engrave or print their logos, batch numbers, and other details on the product they are manufacturing. You can cut a wide range of materials with different thicknesses with the help of lasers. There is a sharp laser beam that is used to melt, burn, or vaporize the materials.

Laser cutting is a kind of fabrication process that will use a thin laser beam to either cut or etch the material into a wide range of designs, patterns, and shapes as specified by the designer. This thermal-based fabrication process is ideal to be used for various materials such as wood, glass, plastic, paper, metal, and gemstone. This can produce intricate parts without using any custom-designed tool.

Working of laser cutting

The diameter of the laser cutting beam would range from 0.1mm to 0.3mm, and the power of it would be from 1 to 3 KW. However, you can change the power based on the material you want to cut and its thickness. If you want to cut the aluminum material, you would require 6 KW of power. It is not recommended to cut the metals such as aluminum and copper since these materials will have high heat conductive and reflective properties. To cut these meals, you would need high power.

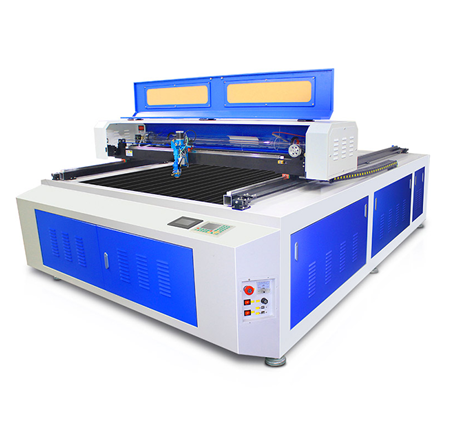

Few of the core components of laser cutter include:

Laser resonator: There is a laser light that comes from the laser resonator and is passed through the airtight glass tube that has two mirrors that are facing each other. This tube is filled with gases such as hydrogen, nitrogen, and helium. These gases are mixed and get activated with the help of diodes, or they will be an electric discharge that produces energy in the light form.

Cutting head: The light that is reflected would pass in different directions using the mirrors that are positioned in various angles so that it will go and hit the laser cutting head. When the beam hits the laser cutting head, it will move towards the curved lens and is magnified and projected to a single point. In this cutting head, the laser would get converted into a thin and focused beam, which you can cut with ease. This focused beam would go through the nozzle prior to it passing through the plate that has nitrogen or oxygen gas, which again flows through the nozzle. For instance, if you want to cut an aluminum or stainless steel material, the laser beam that is passed would melt this material before the nitrogen hits the molten metal. This cutting head is joined adjacent to the mechanical system, which is driven with the help of a belt that allows you to move in a specific area. The lens would focus on the material surface so that the laser can cut the material precisely.

Nozzle distance: There is a good amount of distance that is maintained between the plate and nozzle. Space is what determines the focal point. The cut quality is based on the focal point. If you change the focal point, then it also changes the quality of the cut. There are a few other factors that will have an impact on cut quality. These include – beam intensity and speed.

Types of laser cutters

There are different types of laser machines available in the market to carry out different laser cuts. The laser cutter you use will be based on the thickness of the material. You need to choose the one that can cut the thickness of the material you are using with ease. You can use a high powered laser for various applications where you would need to cut a lot of plastic or metal materials. On the flip side, the low power laser is used to cut thin materials such as paper, wood, card stock, and plastic.

Three types of laser cutters include:

Gas lasers: This is also called a CO2 laser cutter. The cutting of the material precisely will be done by using electrically simulated CO2. This type of laser is produced by mixing the gases such as nitrogen and helium. This CO2 laser will have a lot of energy to cut the material over the fiber laser that uses the same amount of power as CO2. The CO2 laser is better to cut thick materials with smooth finishing. This is the widely used laser to cut the materials as it is cost-effective and highly efficient. Examples of materials you can cut using this type of cutter include plastic, foam, wood, acrylic, and so on.

Crystal laser cutter: This type of cutter will produce beam through neodymium-doped yttrium ortho-vanadate and neodymium-doped yttrium aluminum garnet. This type of cutter is ideal for cutting thick and robust materials. However, this uses a tiny wavelength when compared to the CO2 laser cutter. This uses high power, so its components get worn out at a faster pace. Examples of materials that you can use to cut include ceramics, metals, and plastics.

Fiber laser cutter: The cutting of material is carried out with the help of fiberglass. The beam is produced using the seed laser, which is later improved with the glass fiber and pump diodes. The wavelength used by this cutter is 1.064 micrometers. The beam used by this cutter is 100 times greater than that of a CO2 laser cutter. This type of cutter is used to cut both the metal and non-metal materials. This laser has no moving parts, unlike the gas laser; therefore, it is energy efficient and would cut reflective materials without any reflections projecting back. This requires minimal maintenance and is cost-effective.

Of all these types of cutters, the widely used is the CO2 laser by the professionals. This can cut non-metal materials. However, the latest cutters can cut even the metals. This can cut organic materials and carry out the engraving process on rough materials.

The laser cutters are widely used to create prototypes and are used by artists who want to bring their digital designs into reality. Also, industries will use it to cut materials.

Do you want to buy a laser cutting machine? Emit is professional laser cutter manufacturer, you can find more laser cutter: https://emitlaser.com/product-category/laser-cutter/