In the manufacturing of modern plastic, twin screw extruders are an indispensable tool. They are vital in the production of a variety of items from raw plastic to masterbatches however they are not detailed enough for more complex intricacies. A twin screw extruder manufacturer can be any stem that has a basic understanding of extrusion technology because it is more than just compounding work; it’s the future of innovation.

In this site, I will be shedding light on what twin screw extruders are, their advantages, their uses and how to choose the best manufacturers available in the market.

For more in-depth information you should view from twin screw extruder manufacturers – UDTECH

Twin Screw Extruder Machine and Its Functioning

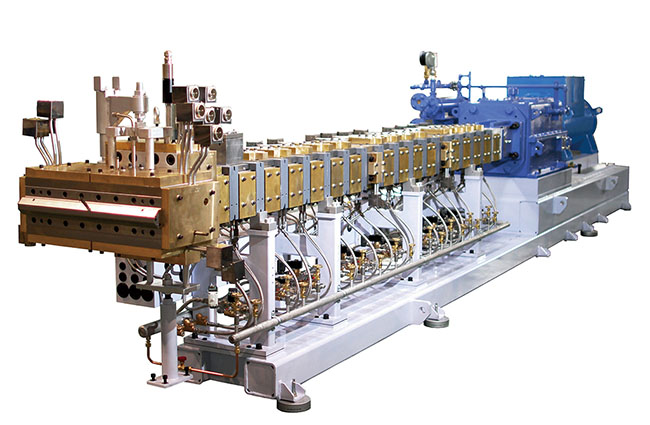

In the simplest words, a twin screw extruder is a complex machine which helps in working wings with plastics, for the purpose of compounding and shaping. It makes use of two intermeshing screws which are situated within a barrel to help in melting and combining different materials within materials. A high torque gearbox powers this device, which draws materials from a hopper into the gear, where they are directed into mixing zones and then extruded through a die to form the desired structure.

Deep Diving in the Concept Behind Twin Screw Extruder

This mechanism operates on the principle of two screws rotating in opposite directions: the screws are placed in a heated barrel at its center.

Screwing generates pressure and shear that influence the flow of materials while providing a means to guarantee a consistent blending of fillers and additives. This specific control makes twin screw extruders essential equipment in complex plastic processing operations.

The Functions of the Screw and Barrel in the Extrusion Process

The screws and the barrel comprise the core of a twin screw extruder. Each of these components has a role in the process of extruding:

Screw placement allows for the movement of material to be mixed, melted, and pumped.

The barrel acts as a containment and heating device, maintaining the parameters of the process.

Both materials need to be impact-resistant and non-wearable, particularly in regard to tools that utilize manufacturing and high heat.

What Twin Screw Extruder Business can Instrument?

When looking at the two, twin screw extruders are easier to use in saving time energy and power, whether it is precise blending of materials to the requirements of the final product, to the target quantity.

Advantages of Co-Rotating Twin Screw Extruders

Creating uniform compounds and masterbatches for high-quality plastics is only possible with the aid of co-rotating twin-screw extruders since they offer exceptional mixing and kneading capabilities.

These include but are in no singular way limited to:

Enhanced Mixing: Their intermeshing screws ensure homogeneous dispersion.

High Output: Efficient in processing larger material volumes.

Versatility: For plastic recycling and compound production, wide applications are applicable.

Extrusion Technology for Plastic Manufacturing

With twin-screw extruder features such as heat control, mechanical screw control that is both adjustable and fixed and high torque, cut down on polymer processing time as well as film and sheet extrusion.

High Torque capabilities Extruders

Torque is an important consideration in extrusion technology.

High torque twin screw extruders can enhance material throughput, expanding business production potential without significantly raising the running costs.

How to Select the Right Twin Screw Extruder Manufacturer

Choosing a twin screw extruder manufacturer can determine the competitive edge of your business. The following sections will guide you in identifying the best manufacturer for your needs.

Evaluating Extruder Manufacturer Expertise

The offering of extrusion technology should be a key consideration while evaluating a manufacturer. Look for expertise in:

Screw design.

Feeding systems and barrel design.

Control systems and process management.

The means of manufacturing custom designed products to suit particular application requirements is also critical.

Key Considerations for Extrusion Machine Purchase

The following are the key aspects that one should consider when acquiring a twin screw extruder:

Material Compatibility – It is important to make sure that the extruder is compatible with the designated materials to be used.

Machine Durability – The quality of the machine and the abrasion resistance should be checked.

After-Sales Support – Good manufacturers have a proper service structure in place and spare parts can also be obtained easily from the manufacturer along with technical support.

Energy Efficiency – Today’s extruders should have low energy consumption for optimal performance.

Comparing Extruder Market Leaders

KraussMaffei and Leistritz are regarded the world leaders of extruder manufacture; however, their reputation does not discourage the search of new manufacturers who offer superior technology at competitive rates.

What are the Applications of Twin Screw Extruders?

In the plastic manufacturing sector, twin screw extruders are utilized for:

Plastic Recycling: They transform post-consumer plastics into reusable granules.

Masterbatch and Compound Production: These sorts of extruders are ideal for blending colorants, other materials, and fillers efficiently.

Polymer Processing: The possibility of transforming polymer materials from pellets into films is easily facilitated by twin-screw extruders or compounding equipment.

Advancements in the Control of Extruders

Currently, process control systems can be found on modern extruders. Such innovations feature, monitoring of the process and quality control in real time, more robotic interventions, and other measures that even center on reducing waste and increasing efficiency which is vital for mass production companies.

Who Dominates the Extruder Manufacturing Space in the Market?

In the market, there are already manufacturers who have proven to be trustworthy and innovative and are notable for their cutthroat edge.

Brief Summary of KraussMaffei, Leistritz and Others.

KraussMaffei offers a range of motors under its brand catered towards mass production that includes customizable elements.

Leistritz collagen Master Extruders provides co-rotation twin screw extruders equipped with leading edge process technology.

UDTECH provides extrusion alternatives suitable for present day manufacturers that maximizes production while minimizing energy expenditure.

View twin screw extruder manufacturers – UDTECH for More Details

The Importance of Spare Parts and Gearbox in Maintenance

The use of grams with spare parts would mitigate those risks. Maintenance of that kind when combined with the availability of spare parts reduces inactivity of the equipment and increases productivity.

Innovations by UDTECH and Other Manufacturers of Twin-Screw Extruders The new players within the market such as UDTECH are using screw design and process control innovations to provide advanced solutions at lower prices. Enhanced wear resistance, adjustable screw types, and cooling systems for components are all examples of these advancements. Select the Appropriate Twin Screw Extruder and Revolutionize Your Manufacturing Plant. The right twin screw extruder and the right manufacturer can completely change the way you do your plastic manufacturing processes.

These machines are however extremely useful and multifaceted whether your intention is to produce masterbatches, recycle materials, or use new polymers. Take in to account industry experience, machine sturdiness, and after sale service of the potential manufacturer so that your investment pays off with enhanced value over time. Between KraussMaffei, Leistritz and the recent players like UDTECH, extrusion technology opportunities can best be suited for the evolutionary companies.