In industrial automation, signal conditioners play a crucial role in ensuring that data from various sensors and instruments is accurate, reliable, and usable. They act as a bridge between sensors and control systems, transforming raw signals into a form that can be easily understood and used by automation equipment. This article explores the benefits of using signal conditioners in industrial automation and why they are essential for modern industrial operations.

1. What Is a Signal Conditioner?

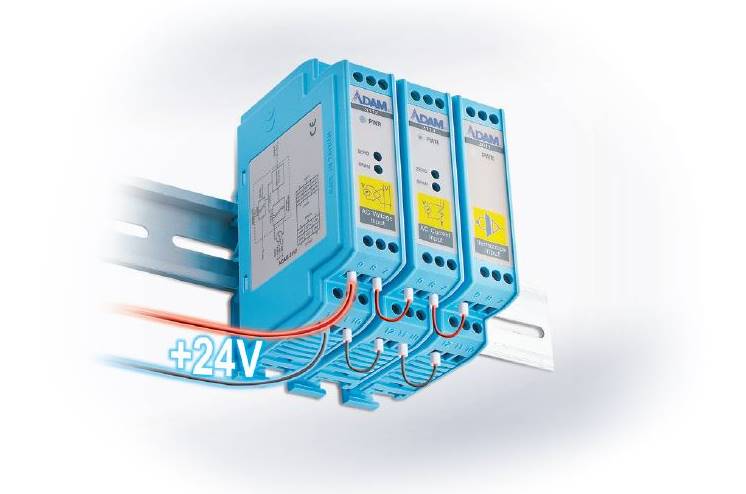

A signal conditioner is a device used to modify, improve, or convert signals from sensors and other input devices before they are sent to control systems or monitoring equipment. These devices are designed to handle different types of signals, such as voltage, current, temperature, and pressure, and ensure that these signals are accurate and stable.

Signal conditioners can perform various functions, including amplification, filtering, isolation, and conversion. By doing so, they enhance the quality of the signal and make it suitable for further processing or analysis.

2. Improved Signal Accuracy

One of the primary benefits of using signal conditioners is improved signal accuracy. Sensors in industrial environments can produce signals that are affected by noise, interference, or other factors. Signal conditioners can filter out unwanted noise and interference, ensuring that the signal received by the control system is as accurate as possible.

For example, if a temperature sensor generates a signal that is weak or noisy, a signal conditioner can amplify the signal and remove any noise, providing a clear and precise temperature reading. This accuracy is crucial for maintaining the quality and safety of industrial processes.

3. Enhanced Signal Stability

Signal conditioners also help in enhancing signal stability. In industrial settings, signals can fluctuate due to various factors, such as electrical noise, temperature changes, or mechanical vibrations. These fluctuations can lead to unreliable data and affect the performance of automated systems.

Signal conditioners stabilize the signal by filtering out fluctuations and providing a steady output. This stability ensures that control systems receive consistent data, leading to more reliable and predictable operation of machinery and processes.

4. Protection from Electrical Interference

Industrial environments often have high levels of electrical interference from machinery, power lines, and other sources. This interference can disrupt the signals from sensors and affect the performance of control systems.

Signal conditioners offer protection by isolating the signal from electrical interference. They achieve this through isolation techniques, such as using optocouplers or transformers, which separate the signal from the source of interference. This protection ensures that the signal remains clean and unaffected by external electrical noise.

5. Compatibility with Various Signal Types

In industrial automation, different types of sensors and instruments generate different types of signals, such as analog voltage, current, or digital signals. Signal conditioners are designed to handle a wide range of signal types and convert them into a standard format that can be easily processed by control systems.

For instance, a signal conditioner can convert a temperature sensor’s analog voltage signal into a standard current signal that is compatible with a control system. This versatility allows for the integration of various sensors and instruments into a single automation system.

6. Simplified System Integration

Signal conditioners simplify system integration by providing a uniform interface for different sensors and instruments. Without signal conditioners, integrating sensors with different signal outputs into a control system could be complex and require additional conversion equipment.

Signal conditioners streamline this process by converting all signals to a common format, making it easier to connect and integrate different components. This simplification reduces the need for complex wiring and additional equipment, leading to a more efficient and cost-effective automation system.

7. Increased System Reliability

Reliability is a critical factor in industrial automation. Any failure or error in the signal transmission can lead to operational issues, downtime, and even safety hazards. Signal conditioners enhance system reliability by ensuring that signals are accurate, stable, and free from interference.

By providing consistent and reliable signals, signal conditioners contribute to the overall reliability of the automation system. This reliability is essential for maintaining smooth and uninterrupted operations, reducing the risk of equipment failures, and improving overall productivity.

8. Flexibility in Application

Signal conditioners offer flexibility in various industrial applications. They can be used in a wide range of industries, including manufacturing, energy, automotive, and process control. Their ability to handle different types of signals and perform various functions makes them suitable for diverse applications.

For example, in a manufacturing plant, signal conditioners can be used to process signals from temperature sensors, pressure sensors, and flow meters, ensuring that all data is accurately transmitted to the control system. This flexibility allows for the customization of automation systems to meet specific requirements and applications.

9. Cost-Effectiveness

While signal conditioners may represent an initial investment, they can lead to cost savings in the long run. By improving signal accuracy, stability, and reliability, signal conditioners reduce the risk of errors and equipment failures. This reduction in errors can lead to fewer maintenance costs, lower downtime, and increased productivity.

Additionally, signal conditioners simplify system integration and reduce the need for additional conversion equipment, further contributing to cost savings. Overall, the benefits of using signal conditioners often outweigh the initial costs, making them a cost-effective solution for industrial automation.

10. Future-Proofing Your System

As technology evolves, industrial automation systems need to adapt to new sensors, instruments, and control technologies. Signal conditioners help future-proof your automation system by providing compatibility with various signal types and formats.

When new sensors or instruments are introduced, signal conditioners can easily accommodate these changes by converting signals to a compatible format. This adaptability ensures that your automation system remains up-to-date and capable of integrating new technologies without significant modifications.

Conclusion

Signal conditioners are essential components in industrial automation, offering numerous benefits that enhance the performance and reliability of automation systems. By improving signal accuracy, stability, and protection from interference, signal conditioners ensure that data from sensors and instruments is accurate and reliable.

Their ability to handle various signal types, simplify system integration, and provide flexibility in applications makes them a valuable addition to any automation system. Furthermore, signal conditioners contribute to cost savings and future-proofing, making them a smart investment for modern industrial operations.

In summary, incorporating signal conditioners into your industrial automation system can lead to more efficient, reliable, and cost-effective operations. Whether you’re optimizing existing systems or designing new ones, signal conditioners play a crucial role in achieving success in industrial automation.