Film capacitors are widely used passive components that consist of an insulating plastic film dielectric such as polypropylene or PET, with thin metal layers forming conductive plates. Known for its self-healing properties and ability to withstand high voltages and currents while maintaining reliability under power demands, the plastic film capacitor has become increasingly essential in electric vehicles (EVs).

As EVs adopt more powerful battery packs and electric motors, their electrical systems require components suited to the unique technical requirements for reliable energy storage and electronics in high voltage, pulsed load applications. Plastic film capacitors meet these needs through qualities like self-healing protection, high voltage tolerance, the ability to handle currents efficiently at small sizes, and long operational life even under dynamically changing loads.

Plastic Film Capacitor: Top Features for New Energy Vehicles

The popularity of the plastic film capacitor in new energy vehicles is not surprising given its useful properties that make it suitable to the challenging demands of automotive power systems. Its key features for new energy vehicles include:

- Self-Healing Characteristic

When minor damage occurs to the dielectric layer from voltage spikes or other transient events, the material of the film capacitor can automatically repair and reseal thin areas. This self-healing trait ensures reliable performance can be maintained over the extensive operating life expected in electric vehicles.

- Withstand High Voltage

Plastic film capacitors utilize polypropylene and other dielectric films that have excellent insulation capabilities, allowing high operational voltages. High voltage tolerance is important in EVs that rely on high-capacity lithium-ion battery packs with substantial energy and power capabilities.

- High Reliability

The combination of self-healing film, epoxy sealing, low ESR winding construction, and other attributes contribute to reliability in the film capacitor that far surpasses electrolytic or ceramic types. The capacitor demonstrates consistent performance even after thousands of charge/discharge cycles.

Challenges of Capacitors in Electric Vehicles

While the plastic film capacitor offers advantages well-suited for electric vehicles, its use in automotive power systems is not without challenges that manufacturers continue working to overcome. The most common challenges include:

Higher Working Voltage

As EV batteries scale to provide longer range per charge, higher voltages are becoming more common. This requires film capacitors to achieve working voltages sufficient for withstanding not only normal usage but also regenerative braking energy feedback to the battery.

Smaller Size

As automakers strive for more compact layouts of electrical compartments, there is pressure to miniaturize all components, including the plastic film capacitor. Reduced size is challenging due to the inherent volume needed by the capacitor package, foils, and dielectric material to provide necessary capacitance values at higher voltages.

Higher Reliability

The pulsating load profile from frequent acceleration and braking places tough demands on a capacitor’s ability to withstand current surges and temperature fluctuations over many thousands of hours of service. Reliability targets are high, as any failure could leave the vehicle stranded. Plastic film capacitor makers must thoroughly test designs to prove the performance and lifespan that automotive clients require.

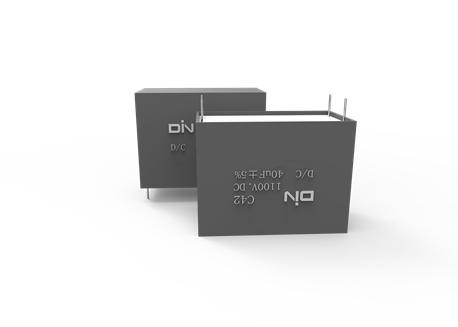

Product Highlight: C42 DC-Link Capacitors

Founded in 2001, DIN Electronics manufactures a wide range of high-performance capacitors with plastic film technology. As an innovative capacitor manufacturer and supplier, DIN Electronics has an independent product reliability lab that adheres to IEC and GB standards. The company’s R&D team works closely with customers to design cost-effective, customized solutions.

The C42 DC-Link Capacitors from the brand are specifically designed for applications, including inverters that are well-suited for electric vehicles. These capacitors utilize plastic box construction with metalized polypropylene film. They are ideal for use in new energy vehicles due to their small size and suitability for voltage requirements. Their key features include:

- A highly insulating polypropylene film dielectric provides strength and insulation

- Operates continuously from -40°C to 85°C, ensuring reliability

- Rated up to 1200V DC for substantial power storage abilities

- 68μF to 110μF capacitance range

- Robust plastic case with UL 94V-0 flame resistance

- Non-inductive winding for low-resistance connections

- Low ESR and ESL allow efficient energy transfer with minimal loss

- Handles high pulse currents and dv/dt for rapid switching loads

Overall, the polypropylene film capacitor offers compelling advantages for energy storage and power conditioning applications in EVs. Manufacturers like DIN Electronics are helping push the technology forward through reliable products that are developed with self-healing properties, high voltage capabilities, and small sizes required by automotive clients. The manufacturer is committed to innovation and exceptionally high standards demanded by industries, accelerating the global transition to renewable energies. Contact DIN Electronics for more details on its reliable plastic film capacitor products.