Downstream extrusion is a vital process in plastic manufacturing, ensuring that extruded materials are properly shaped, cooled, and finalized to meet specific industry standards. This article explores the complete process of downstream extrusion, focusing on its definition, the essential downstream extrusion equipment used, the various materials involved, and its broad applications.

We will start by defining downstream extrusion and outlining its importance in shaping materials like plastics, metals, and rubbers. Key equipment such as pullers, cutters, tanks, cooling systems, and winding systems play a critical role in controlling speed, temperature, and dimensions, ensuring the final product meets required specifications. From pipes, profiles, and films to fibers, wires, and coatings, the applications of downstream extrusion are vast, spanning industries like automotive, medical, construction, and consumer goods. Moreover, technological advancements and best practices in the field are driving more efficient, sustainable manufacturing processes.

Whether you’re involved in extrusion or simply curious about this essential manufacturing process, this guide will provide you with all the information you need to understand how downstream extrusion works and its significance in today’s industrial landscape.

What is Downstream Extrusion?

Downstream extrusion is a crucial stage in the plastic manufacturing process that occurs after the initial extrusion of raw plastic materials. It involves the use of various equipment and processes to further shape, cool, and finalize the extruded plastic product. This stage is essential for achieving the desired properties, dimensions, and quality of the final plastic item.

What Are The Equipment Used in Downstream Extrusion?

Downstream extrusion involves several specialized pieces of equipment, each playing a crucial role in processing and finalizing the extruded plastic product. The main equipment used includes:

Pullers

Pullers are essential devices that draw the extruded material through the production line at a controlled speed. They maintain tension and help ensure consistent dimensions of the extruded product. Common types include:

- Belt pullers: Use friction between belts to pull the material

- Caterpillar pullers: Employ continuous treads for grip and pulling

- Roller pullers: Utilize rotating rollers to guide and pull the extrusion

Cutters

Cutters are used to separate the continuous extruded product into desired lengths. They come in various forms:

- Rotary cutters: Use spinning blades for quick, clean cuts

- Flying knife cutters: Move along with the extrusion to make cuts without stopping the line

Puller / Cutter Combination

These integrated units combine pulling and cutting functions in a single machine. Benefits include:

- Improved synchronization between pulling and cutting operations

- Space efficiency in the production line

- Often allows for more precise length control

Saws

Saws are cutting devices used for harder or thicker extruded materials. Types include:

- Traveling saws: Move along with the extrusion to make cuts

- Stationary saws: The extrusion is stopped momentarily for cutting

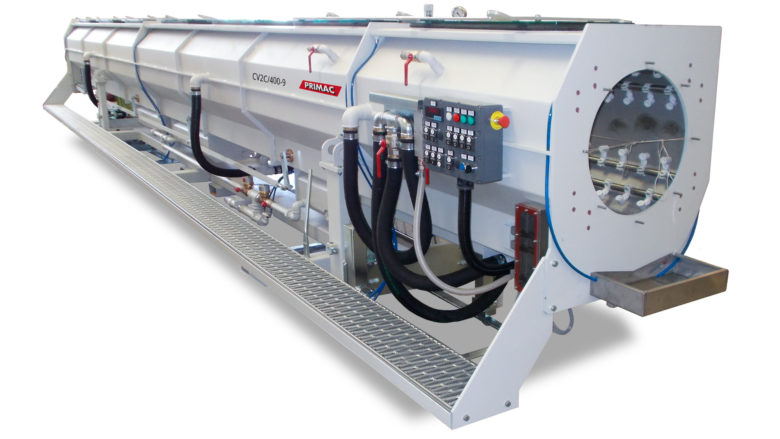

Tanks

Tanks play a crucial role in cooling and shaping the extruded product:

- Cooling tanks: Filled with water or other coolants to solidify the extrusion

- Vacuum sizing tanks: Use negative pressure to maintain the product’s shape during cooling

- Calibration tanks: Help ensure the extruded product maintains proper dimensions

Winding Systems

Winding systems are crucial components in downstream extrusion processes, particularly for producing flexible, continuous products such as films, sheets, fibers, or cables. These systems are responsible for collecting the extruded material into manageable rolls or spools for storage, transportation, and further processing.

Cooling Systems

Cooling systems are essential components in downstream extrusion processes, playing a critical role in solidifying and stabilizing the extruded plastic material. These systems are designed to remove heat from the extrudate in a controlled manner, ensuring proper formation and preserving desired properties.

These equipment pieces work together in the downstream extrusion process to control the speed, shape, temperature, and final dimensions of the extruded product. Their specific configuration depends on the material being extruded and the desired characteristics of the final product.

What Are The Types of Extrusion Materials?

The types of extrusion materials are listed below:

Plastics – Thermoplastics like polyethylene, polypropylene, PVC, and nylon are widely used in extrusion. They can be melted and reformed repeatedly.

Metals – Aluminum, copper, steel, and other metals can be hot extruded into various shapes and profiles.

Rubber – Natural and synthetic rubbers can be extruded to form seals, tubing, and other products.

Ceramics – Some ceramic materials can be extruded when mixed with binders to form shapes that are then fired.

Foods – Many foods like pasta, cereals, and pet food are produced through extrusion cooking processes.

Polymers – Various polymers beyond basic plastics, like fluoropolymers, can be extruded for specialized applications.

What Are The Applications of Downstream Equipment?

The applications of downstream equipment are listed below:

Plastic Pipes and Tubing

Downstream extrusion is widely used to produce various types of pipes and tubes. This includes water and gas distribution pipes, which require precise dimensions and durability. Electrical conduits are extruded to protect wiring in buildings and infrastructure. Medical tubing, crucial for healthcare applications, demands high precision and cleanliness. Automotive fuel lines are another important application, requiring resistance to chemicals and temperature fluctuations.

Profiles and Shapes

This application involves creating complex cross-sectional shapes. Window and door frames are common examples, requiring strength and weather resistance. Weatherstripping is extruded to provide sealing in various applications. Decorative trims for furniture and automotive interiors are also produced using this method. The process allows for intricate designs and consistent quality in long lengths.

Films and Sheets

Extrusion is key in producing thin, flexible materials. Packaging materials, including food wrap and shopping bags, are common applications. Agricultural films protect crops and control growing environments. Geomembranes are used for environmental protection in landfills and reservoirs. Lamination films for documents and packaging are also produced through this process.

Fibers and Filaments

This application creates long, thin strands of material. Synthetic textiles for clothing and industrial use are a major application. Fishing lines require strength and flexibility. Optical fibers, crucial for telecommunications, demand high purity and precision. The growing field of 3D printing relies on extruded filaments as raw material.

Wire and Cable Coatings

Downstream extrusion is used to apply protective coatings to wires and cables. Electrical wire insulation is a critical application for safety and performance. Fiber optic cable jacketing protects delicate glass fibers. Coaxial cable production involves multiple layers of extruded materials for optimal signal transmission.

Extrusion Coating

This process applies a layer of plastic onto another material. Paper and cardboard coating enhances moisture resistance and appearance. Fabric lamination creates waterproof or reinforced textiles. Metal foil coating combines the properties of metal and plastic for packaging and industrial applications.

Medical Devices

Precision extrusion is crucial in healthcare. Catheters require biocompatibility and specific mechanical properties. Stents need to be both flexible and strong. Surgical tubing must meet strict quality and safety standards. These applications often involve specialized materials and clean room production environments.

Automotive Components

The automotive industry relies heavily on extruded parts. Sealing systems protect vehicle interiors from water and noise. Interior trim pieces are extruded for consistency and cost-effectiveness. Hoses and belts require specific mechanical properties to withstand engine conditions.

Construction Materials

Extrusion plays a big role in modern construction. Siding provides durable and attractive building exteriors. Decking materials offer weather resistance and low maintenance. Fencing produced through extrusion is durable and uniform. Insulation panels help improve energy efficiency in buildings.

Consumer Goods

Many everyday items are produced through extrusion. Straws require consistent diameter and food-safe materials. Zipper tapes need precise dimensions for smooth operation. Toothbrush bristles are extruded for uniform size and properties. Disposable cutlery benefits from the cost-effectiveness of the extrusion process.

Packaging

Extrusion is vital in packaging production. Bottle caps and closures require precise threading and sealing properties. Food containers need to be durable and often have specific barrier properties. Protective packaging, such as bubble wrap, relies on extrusion for its unique structure.

Recycling

Downstream extrusion is increasingly important in plastics recycling. It allows for processing recycled plastics into new products, helping to close the loop in plastic waste management. This application can involve challenges in maintaining consistent quality due to variations in recycled input materials.