Profitability is the prime factor in any production process. While you can optimize material cost and time spent on production, there is another way to increase the profits of a production operation. By implementing a production management system, a company can improve results without compromising quality or safety. However, a well-developed system offers additional latent benefits to companies that further enhance their value potential. Consider these benefits when evaluating the cost analysis of implementing the system in your company.

Production Management Systems Offer Connection Capabilities

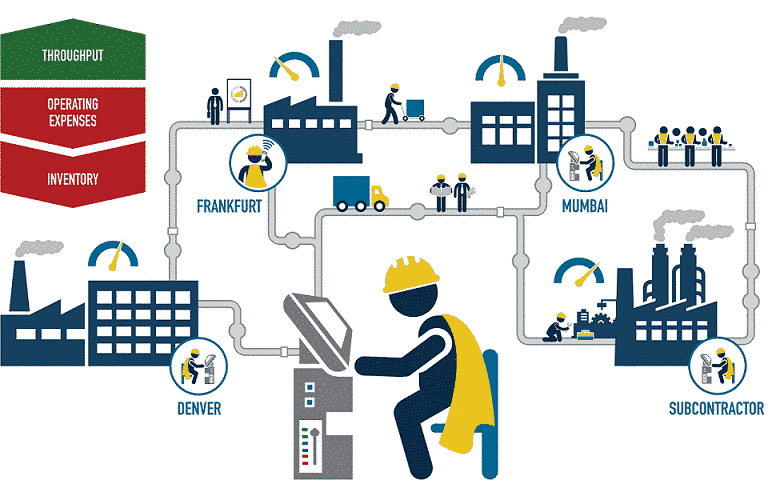

A production management system is developed to gather and store the production information of a factory. As such, the system is networked to be integrated with equipment and other software such as work order software to facilitate data collection. Controllers and managers are trained in the process and assist in this process of data collection. Finally, the company’s business applications are linked for a complete system.

As a consequence of this connection, a production facility achieves total transparency, control and optimization with production. Each step, from ordering and product development to process control and production output, is documented and analyzed. Errors or failures that cost time or money can be easily identified and corrected or replaced. This connection capability significantly increases the efficiency and capacity of manufacturers of all sizes.

Reduces Waste

Thanks to the use of a production management system, a production plant can reduce waste in several areas. First, it is a computerized system that involves digital master records, as well as an electronic remittance and device history records. For an office location, this means little need to keep paper copies of the documentation. Filing, storing, and time spent tracking paper work is no longer a factor in time and expense between offices. With regard to the time saved, when using an electronic data entry system, the use of back-office automation helps reduce the time of data entry.

Another instrumental area of waste reduction is in the production plant. Using a production management system reduces scrap and waste material through settings that are consistent and optimized. If there is a problem with a step in the production process, the system will detect the problem in real time, and the production process is paused until the problem is corrected. This is a significant cost-saver considering how many products could be improperly produced in a few hours.

Increases Productivity

Likewise, a production management system is highly effective in increasing productivity in both front and back office as well as in a production line. When everyone is in the same rhythm, there is no room or opportunity for error. The system keeps all members of a production team at the same pace on total productive maintenance.

For example, consider that a material needed for production is not available in stock. Instead of wasting time contacting several individuals in search of the material, everything is recorded in a universal system accessible by all team members. Everything from properly maintained machinery to the inventory of resources and the correct instruments for a project is documented through this system. Increasing productivity also increases uptime, which is paramount to the success of any production facility.

Minimizes Inventory of Products and Materials

Using an production management system allows manufacturers to be sure about the amount of material and finished product they need for the immediate future. In addition, the system documents and tracks purchases and shipments so that a production facility can minimize excess inventory.

The benefits of a production management system are remarkable in terms of productivity and profitability. However, there is an additional reason why manufacturers are migrating to a digitally based production management system. In this modern era, everyone is migrating to digital.