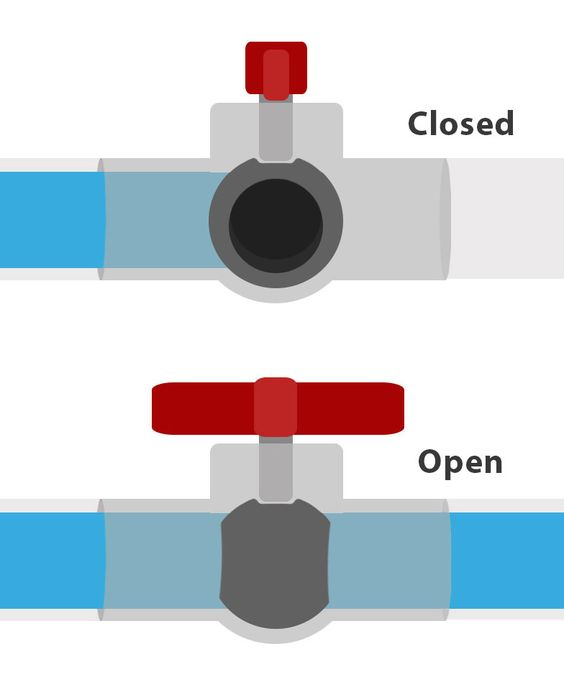

Ball valves belong to the quarter-turn valve family. These valves can make a ninety-degree motion, allowing or stopping the flow of media through a ball-like tool found inside the valves.

They are easy to operate and can be relied upon a tight shutoff for industrial applications. On the other hand, ball valves should not be used for the partially open or close manner in flow regulation since the pressure may affect some valve parts.

This article will lay down necessary information about ball valves that one should know. In addition, it includes a guide about their features, the advantages, and things to be considered when purchasing ball valves.

Application of Ball Valves

Most of the industrial operations require protection from leaks, particularly those industries that need tight shutoff types of equipment. For instance, natural gas industries and chemical industries that are working on purely liquid or gaseous operations. However, slurries do not work well with ball valves.

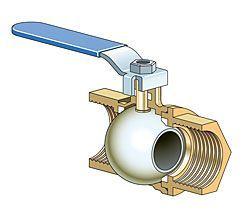

Parts of Ball Valves

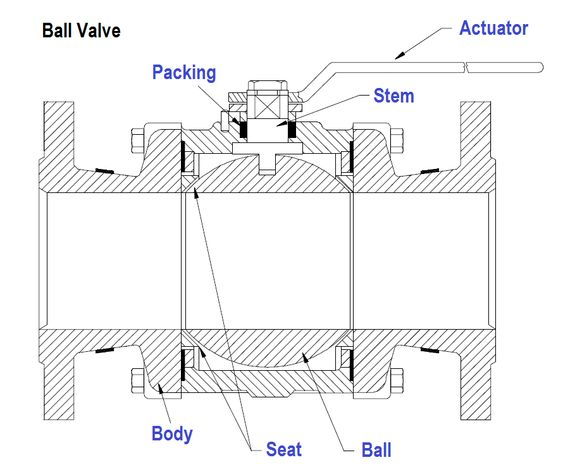

● Body

This is the framework of the valve that keeps all parts altogether. It is bound to the pipes in the piping system, and the body can simply have one, two, or even three pieces.

● Stem

This refers to the shaft that links the inner ball to a handle or actuator. It transfers the movement of the actual quarter-turn force from the handle to the remote ball part.

● Ball

The ball part is the hollow sphere situated in the middle of the valve. It either allows or stops the media from passing through whenever the actuator is turned.

● Packing

This section avoids any leakage from the valve that might escape to the external environment.

● Bonnet

This piece is the housing that conceals both the stem and the packing, which also provides tertiary leakage protection.

● Seat

This item seats the ball part in the valve, which offers a secondary protection layer from possible leakages as the valve closes.

● Actuator

This element is found outside the body, where it opens or closes the valve.

Operation of Ball Valves

These valves can be two-way or more. It actually depends on the number of ports. For example, a two-way valve can be bidirectional, which means there are two seats. The first seat is for the flow, and the second is for the downflow. Several ball valves permit many directional flows, which are cost-effective for some applications. As mentioned above, a ninety-degree turn can open or close the pathways.

Why Prefer Ball Valves?

● Cost-Effective

These valves do not cost much but guarantee that they last for a long time, and they are excellent in gas and water piping systems. There are many choices because of the different designs available worldwide. Like tubomart. com, a company that consistently innovates its piping tools will surely appeal to gas piping and water piping systems.

● Easy Operation

It will only take a quarter-turn to turn on or shut down the tool entirely.

● Easy to Repair

Due to its simple design, repairing and assembling them is more comfortable and quicker compared to other complicated types of valves.

● Pressure Drop

It signifies the unnecessary higher and powerful pump to move the fluid and gas. This reflects the minimal change of pressure from high to low, ensuring the smooth running of pipe features.

● No Stem

Ball valves do not include a stem that pops up or down depending on the motion. Thus, the pipe releases no liquid or gas whenever the valves are turned or shut off.

● Versatile

Ball valves can support high temperatures and high pressures, depending on the composition of materials.

Things to Consider When Purchasing Ball Valves

- Size – sizing matters since it affects the flow of the liquid or gas.

- WOG – it refers to the material passing through the valve and pipes, which is water, oil, or gas.

- Body Material – there are bronze or brass types, but the steel ball type is the most common one.

- Ports – these are the entry and exit points of valves, which can either be standard or full. They can restrict fluid or gas flow.

- Entire Piping System – the valves should be relevant and suitable for the structure of the entire piping system.

- Industry Standards – following what the industry requires, which will ensure minimal errors, accidents, and the likes.

- Seat Material – can be soft-seated or metal-seated, depending on the application it will be used.

Conclusion

To sum it up, ball valves have considerable significance to several sectors like the natural gas and chemical industries because they work well in gas and water piping systems. The main advantages of these valves are easy to use, cost-efficient, and versatile to any application. Most profoundly, they can be relied on to tight-sealing. In buying ball valves, there are several things that an end-user should consider, may it be for industrial or household use.