With security becoming an ever-growing concern, many businesses are taking steps to protect themselves with an in-house identification system. ID Card printers are used to personalise, print and encode plastic cards which allows for simple staff management.

A card printer is a fantastic way to streamline the day to day operations of any business. Issue staff ID cards on demand or encode cards to grand or restrict access to specific business areas. ID Cards are not limited to staff ID issuance. ID Card printers are used in the educational, government and transport sectors.

Id card printers have become readily available in recent years with dramatic size and price reduction making it more practical than ever to introduce one into your business. However, buying a printer can be confusing, there is a lot of confusing technical specifications and terminology surrounding these machines.

This guide will place you in the best possible position to make an informed decision on purchasing a card printer.

PRINTER TECHNOLOGIES

Desktop card printer machines employ two different methods to transfer the images to cards. The first method is Direct-to-card (DTC)

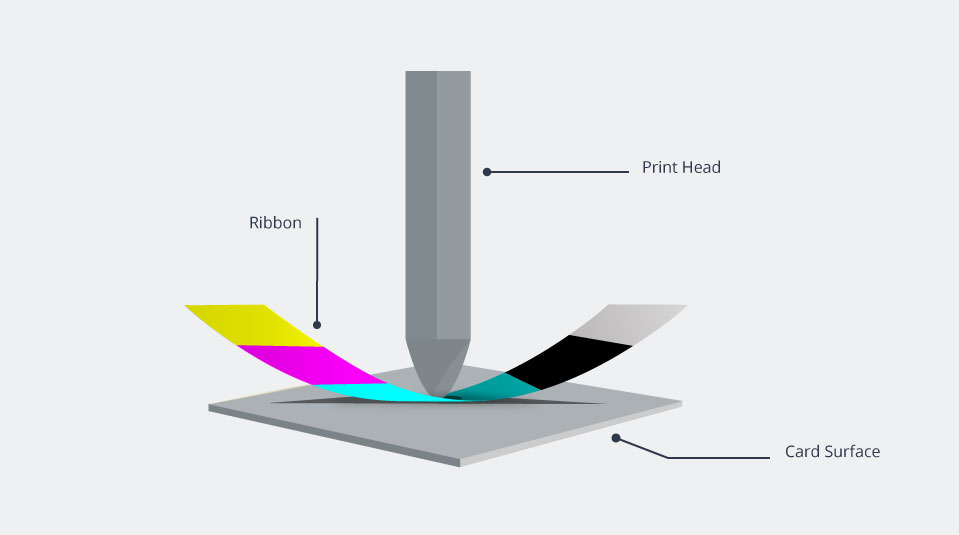

DTC is the most commonly used print method which utilises a dye-sublimation process which uses a thermal print head to vaporise ink within a ribbon and transfer it to the card. The print head passes over each colour panel on a ribbon, heats the ink which vaporises and adheres to the card surface. This method is very quick and cost-effective. These machines have an average print resolution of 300dpi which provides good image clarity and sharp legible text even at smaller font-sizes.

The biggest drawback with these machines is that due to the nature of the print process, DTC printing cannot provide a true edge-to-edge print – a small white border is visible around the edge of the card.

Retransfer printing uses a similar process but first imprints the image on a thin clear film (retransfer film) which is then fused to the card. This comes with significant advantages: Fist, this method allows for over-the-edge printing avoiding the small white border that you get with DTC printing. Print quality is also significantly better and it also allows for printing on uneven card surfaces like chip cards. The trade-off is a much higher price tag along with higher running costs thanks to the addition of the retransfer film. This method is also slower than DTC.

SPEED CAPACITY AND MEDIA

After choosing the print method best suited to your needs, the next step is to choose between single or dual-sided printing. This is very self-explanatory -single-sided machines print on one side while dual-sided print on both. Dual-sided machines make it very easy to print large batches of cards with content on both sides. It should be noted that, you can still use a single-sided printer to print on both sides, it just requires that you manually remove the card and print on the other side. So, this method is usually only employed for those with very small number of cards to print.

Print speed is another important consideration when shopping for a card printer. This is typically a big swaying factor for those with large volumes to print. Large input and output hoppers combined with a fast print speed are the 3 crucial components for high volume issuance.

Another important aspect of printing lies within the print ribbons. Each manufacturer offers different ribbons with different yields. Some may offer 200 prints per-ribbon and some may offer up to 1000. Typically, monochrome ribbons, such as a black (k) ribbon will have a much higher yield than a full-colour (YMCK) ribbon. Its wise to do a little research on the printer consumables before purchase as it will have a big impact on the lifetime cost of the machine.

ENCODING

Card encoding is used widely to improve security. Encoded cards are used for access control, identification and ticketing among others. There are multiple types of encoding each of which requires a specific encoding module.

Magnetic stripes are the simple and most widely used but are slowly giving way to more reliable and secure print methods such as chip encoding. If you need – or may in the future – to encode your cards, you should ensure that you get a printer with a compatible encoder.