What is the Lean Six Sigma methodology?

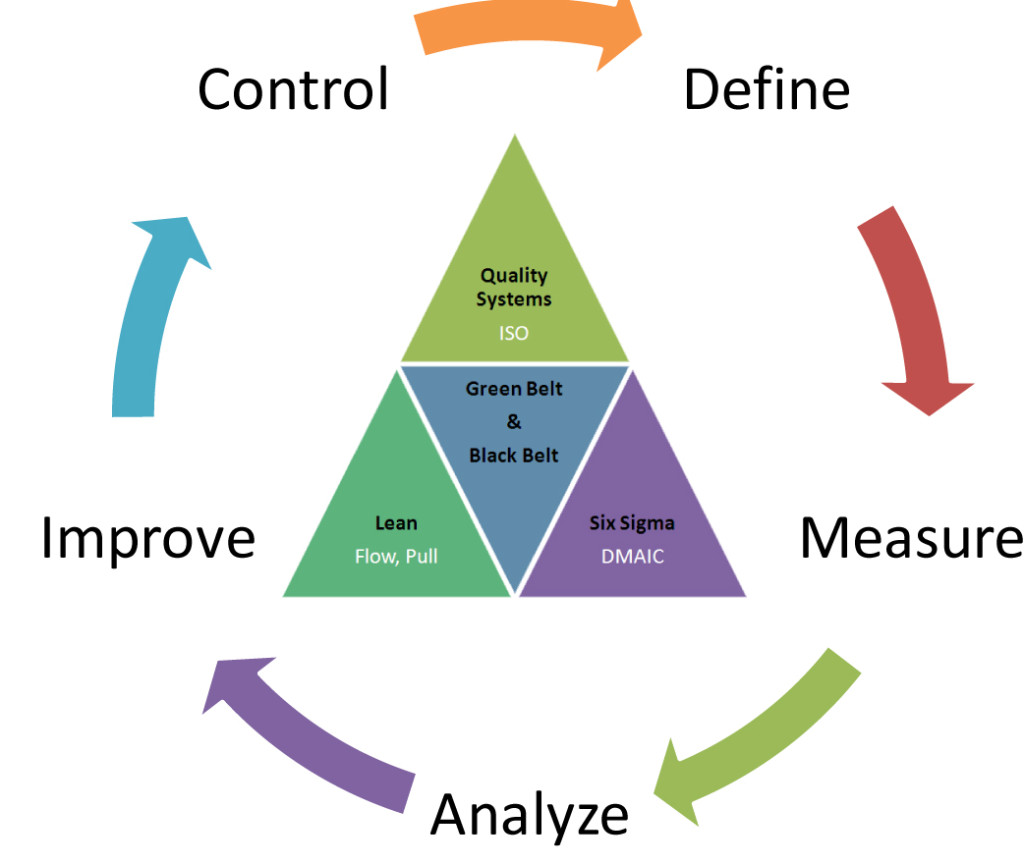

Lean Six Sigma is the combination of two managerial methodologies, Lean and Six Sigma. Lean works on the concept that reduces the waste generated by the industry in terms of defects, overproduction, waiting, non-utilized talents, transportation, inventory, motion, and extra-processing. While Six Sigma Concepts are targeted to improve the quality of the product and minimizing the variability of business performance.

Combined, Lean confirms the connection between the business processes further, and Six Sigma focuses on the process of optimization and improvement. And thereby, reduces the variation of the process. Lean Six Sigma is a quality control strategy and the approaches therein, assist in formulating the quality management roadmaps. Lean Six Sigma undertakes the DMAIC approach to optimize the existing market or supply chain. The six-sigma training guide the manager to implement the strategies on-ground, and lean six sigma certification. Scale their expertise in it.

What is the DMAIC approach in lean Six Sigma Green Belt?

DMAIC approach stands to Identify, Measure, Analyse, Improve, and Control. The DMAIC approach is a data-driven cycle used to eliminate the defect, stabilize the business processes, optimize the design, and improve the organization’s opportunities for business enhancement through five main steps: Define, Measure, Analyze, Improve, and Control. DMAIC method differs from conventional problem solving since it focuses on both quality improvement and the sustainability of the change by correcting the defects in the business procedure.

The essential tools to be used with the DMAIC Approach:

The tools in the DMAIC approach serves the collective purpose of contributing to the success of each of the five phases in the method and assisting in simplifying the preceding and succeeding periods. The tools are secondary because what comprises the foremost requirement of any business tactic is dedicated teamwork. Having mentioned the DMAIC approach, let’s proceed to the tools needed at each phase.

Define

What is the outcome that needs to be measured?

Define is the primary stage of the DMAIC strategy that defines the CTQ (critical to quality) issues and estimates the core business process involved. In this phase, the tools are used to describe various data like customer expectations, the impacted business processes, periphery of the project boundaries, the metrics of quality and performance, and the attitude of Team members as well as the Project Leader.

1. The tools used:

Provide a failure mode and effect analysis

Develop Project Charter

KPIV – Key process Input variable

Volume Stream analysis

Voice of Customer

The needs and wants of other clients

Measure

What is the current performance of the process that is measured?

The Measure stage is performance-oriented. The specifications of the business goals and the impediments obstructing the target are measured at this stage. A data collection plan is framed during this stage to determine the types of defects and metrics. Based on this collected data, the gaps between the current performance and the targeted performance and the existing range of process variation are determined in the next step.

2. The tools Used:

Create a Process map for existing processes

Data collection plan and table

Trend or run charts

Pareto- uneven distribution chart

Control Chart

Process Capability Analysis

Analyze

What are the causes behind the defects? What particularly leads to the problem?

The team has to Analyze the collected data then, as mentioned, and process the gap between existing and required goal performance. The team leader has to reach and trace out the background and immediate cause for the gap and Decide on the processes to be improved. The analysis would also require a validation of the root-cause. The graphs are drawn top project the relative contribution of the defects to the project metrics. An implementation plan is designed to eliminate the errors and generate opportunities after identifying potential solutions against the flaws.

3 . The tools used:

Fishbone

Scatter Plots

5-Why analysis

Process input vs. process output charts

Prioritize potential causes of defects

Improve

How can the real cause be eliminated from the process, or the size of the problem can be reduced?

The implementation plan is brought into action at the Improve Phase. The creative solutions planned in the Analysis process is implemented to fix the shortcomings in the process. The improvements get experimented over Pilot Study and Tests that precisely evaluate the efficiency of the proposed solution. A number of sophisticated tools are deployed in the process to implement the plan and clear off the risk of failure.

4. The tools used:

Brainstorming

Design of Experiments

Pilot-Planning

Plan, Do Check, Act (PDCA) cycle

Failure Mode and Effects Analysis

Deploy improvements

Detailed implementation feedback

Control

Did the process improve? What are the controls placed to sustain the improvements?

Control Phase includes standardization and documentation of the optimized process. The enabled changes are monitored continuously along with the projection of its sustainability in the long run. It is not only the controlling of the changes introduced through the Implement process but also their management with the fixed-wing of the system chain. The team Develops Standing Procedure and Control Plans and accordingly Train the involved staff regarding the new process.

5. The tools used:

Mistake Proofing

Standard Operating procedure

Control chart

Development plans

Audit Plan

Training Plan

Process confirmation

Transition plans

Benefit delivery

6. The most ignored tool in the lean six sigma is “Gratify”

This is a step that remains mostly as an undertone of the entire approach. The process focuses on replicating the changes incorporated through a celebration of the achievements of the business. Whenever an organization proceeds towards achieving a target, it creates an enormous source of growth opportunities. Acknowledging these sources and acquiring a better knowledge of the market through this procedure would improve the company’s value beyond tangible terms. Click Here To Learn Gratify tool Six Sigma Green belt online.

No doubt, this knowledge would enhance the effectiveness of the workers and give them a holistic experience at the workspace. The support of team members to maximize the output of the DMAIC strategy needs to be recognized to foster the relationship between the organization and its employees. Sharing the knowledge of the process within and outside the organization as a mark of celebration doesn’t only provide moral support to the team, but also enhances the reputation of the company.

Replicating the improvements, Sharing the knowledge, encouraging and thanking the team members, further helps the company develop buy-in for the upcoming DMAIC or other strategic improvement initiatives.