The global plastic waste crisis is intensifying, with approximately 400 million tons of plastic waste generated annually. Among this, electronic waste contributes around 2-3%, significantly impacting our environment (Source: Nature; World Economic Forum). Addressing this challenge requires solutions such as extending the lifecycle of products, recycling materials, and developing alternatives to traditional fossil-based plastics.

High-performance polycarbonate (PC) has become essential in various devices, including consumer electronics, industrial automation, and house appliances. Each application presents unique challenges that demand exceptional material performance.

Covestro, a global leader in high-quality polymer materials and components, has a rich history of innovation. As the inventor of polycarbonate, Covestro has been at the forefront of advancing industries with its pioneering and high-impact PC solutions.

Outdoor Applications: Facing the Elements

The outdoor environment poses numerous challenges due to climate, location, and the specific functions of devices. For instance, electric vehicle (EV) charging stations endure prolonged UV exposure and heat during the day, while high-latitude regions face extreme low temperatures in winter, increasing the risk of material cracking. Additionally, housing for base stations must ensure not only excellent signal transparency but also strong dimensional stability to protect internal components from humidity, pressure, or impact.

APEC® XT grades are the ideal solution for these demanding conditions. They remain resilient even in the harshest conditions. The new copolymer technology enables the production of products that exhibit high impact strength even at temperatures as low as minus 40 degrees Celsius. These copolymers have improved chemical and ageing resistance, ensuring long-lasting durability in outdoor applications.

*Source:https://www.nature.com/articles/d41586-023-02252-x; https://www.weforum.org/agenda/2022/12/e-waste-electronic-climate-recycling/

The Makrolon® series also performs strongly outdoors, with specific grades like FR6020 and 6040 series tailored to meet various performance requirements, such as excellent impact resistance, heat resistance with high RTI, flame retardancy, and signal transparency, while maintaining cost efficiency.

Portable Devices: Durability and Lightweight Design

Portable or wearable electronic devices, such as laptop, headphones, AR/VR headsets, mobile phone, require materials that withstand impacts from falls and pressure while remaining lightweight. Additionally, exposure to chemicals from sweat or lotion can weaken housing strength. Modern aesthetics demand compact, durable designs.

Covestro Thin-wall solutions meet these demands by using less material to achieve lightweight yet reliable performance in crack resistance and flame retardancy. Aging tests with cosmetics, such as sun cream, perfume, and face scream, demonstrate their strong chemical resistance, which ensures higher durability of devices.

Sustainable Solutions: Meeting Regulatory and Market Demands

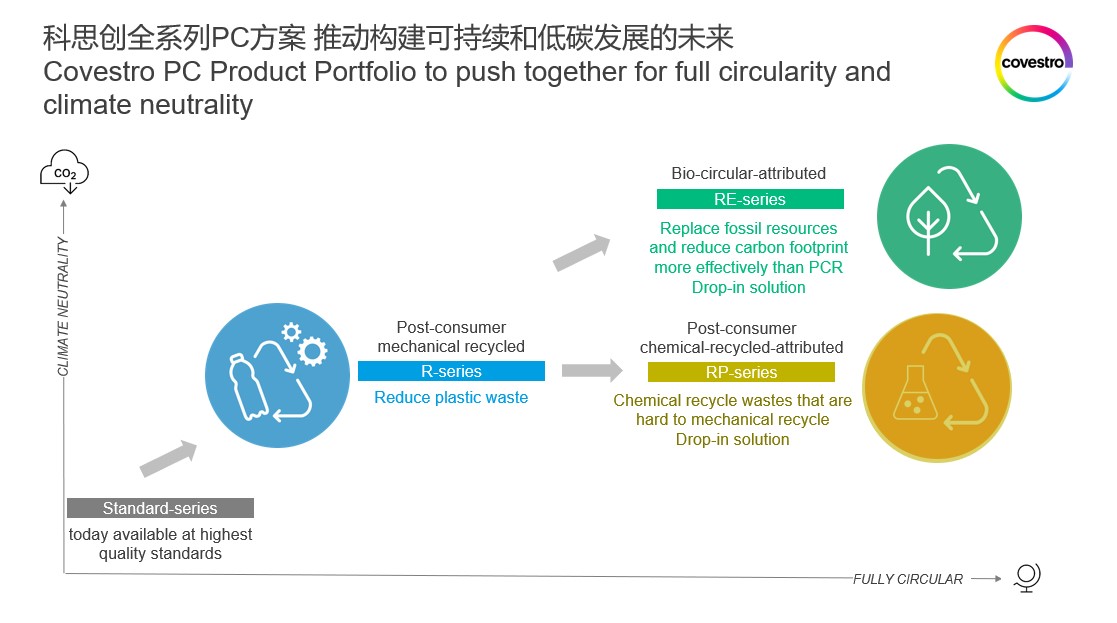

Proper material selection and application can significantly extend the lifecycle of electronic devices, reducing plastic waste. While waste is inevitable, the end of a product’s life does not mean the end of its material. Covestro’s post-consumer recycled (PCR) PC, Makrolon® R series, uses advanced recipes and high-quality feedstocks to reintroduce PC waste into the next lifecycle. Recent advancements have achieved up to 90% recycled content with performance comparable to virgin materials, greatly reducing reliance on fossil-based resources.

In addition to the R series, Covestro recently introduced a range of polycarbonates based on chemically recycled attributed material from post-consumer waste via mass balance: Makrolon® RP. The aim is to manufacture high-quality and durable products with chemically recycled attributed feedstocks. At the end of a long usage phase, the plastics can still achieve a “third product life” through mechanical recycling and the further development of chemical recycling technologies.

Covestro also explores alternative materials from bio-waste and bio-residues: certified mass-balanced grades of the Makrolon® RE series. The RE series is now also available with 25 percent renewable attributed sustainable share.

All three series belong to the Covestro CQ* family, a holistic portfolio of solutions that enables the electronic industry to move away from a linear approach and to materialize the Circular Economy.

Note: CQ is derived from “Circular Intelligence,” a smart approach to more sustainable materials, technologies, and services. Covestro solutions with the “CQ” label are living proof of its CE vision becoming reality. By using alternative raw materials and developing unique new recycling technologies and services, Covestro showcases their Circular Intelligence, transforming the industry to achieve climate neutrality. Learn more at Covestro Solution Center.

The demand for products with recycled raw materials is growing, driven by regulatory requirements and voluntary programs, such as the European End-of-Life Vehicle Directive under review (ELV) and the U.S. Electronic Product Environmental Assessment Tool (EPEAT) for electronics. High-performance recycled and alternative materials support OEMs in meeting these regulations, enhancing sustainability efforts, and opening new business opportunities.

Aesthetics and Consumer Appeal

Aesthetics play a crucial role in consumer electronics, influencing purchasing decisions. Eye-catching designs and colors set trends in the market. Covestro’s high-flow and de-molding capabilities offer design flexibility for creative ideas. Moreover, colorability, color stability, along with rich surface options including glossy, brushed, matte, transparent, translucent finishes, ensure premium user experiences and perceptions.

Interaction among all smart devices is a key factor for user experience, which highly depends on accurate signals. Covestro provides specific polycarbonate with outstanding signal transmittance, ensuring minimal signal attenuation. Meanwhile, visible lights are shielded, even in light color aligning with modern aesthetics needs.

Each year, Covestro launches a CMF (Color, Material, Finish) report, offering design insights based on market observations and customer collaboration. This guides OEMs and brand designers with design and material trends which enable winning consumer attention and gaining market opportunities.

High-performance polycarbonate is increasingly applied in across industries, driven by trends such as the circular economy, Internet of Things (ioT), AI empowerment, and future-oriented compliance. Covestro is committed to being a valued partner for industry players, driving toward a fully circular future with its extensive experience, knowledge, technical networks, and global expertise.

About Covestro:

Covestro is one of the world’s leading manufacturers of high-quality polymer materials and their components. With its innovative products, processes and methods, the company helps enhance sustainability and the quality of life in many areas. Covestro supplies customers around the world in key industries such as mobility, building and living, as well as the electrical and electronics sector. In addition, polymers from Covestro are also used in sectors such as sports and leisure, telecommunications and health, as well as in the chemical industry itself.

The company is committed to becoming fully circular. In addition, Covestro aims to achieve climate neutrality for its Scope 1 and Scope 2 emissions by 2035, and the Group’s Scope 3 emissions are also set to be climate neutral by 2050. Covestro generated sales of EUR 14.4 billion in fiscal 2023. At the end of 2023, the company had 48 production sites worldwide and employed approximately 17,500 people (calculated as full-time equivalents). Learn more at the Covestro Solution Center.