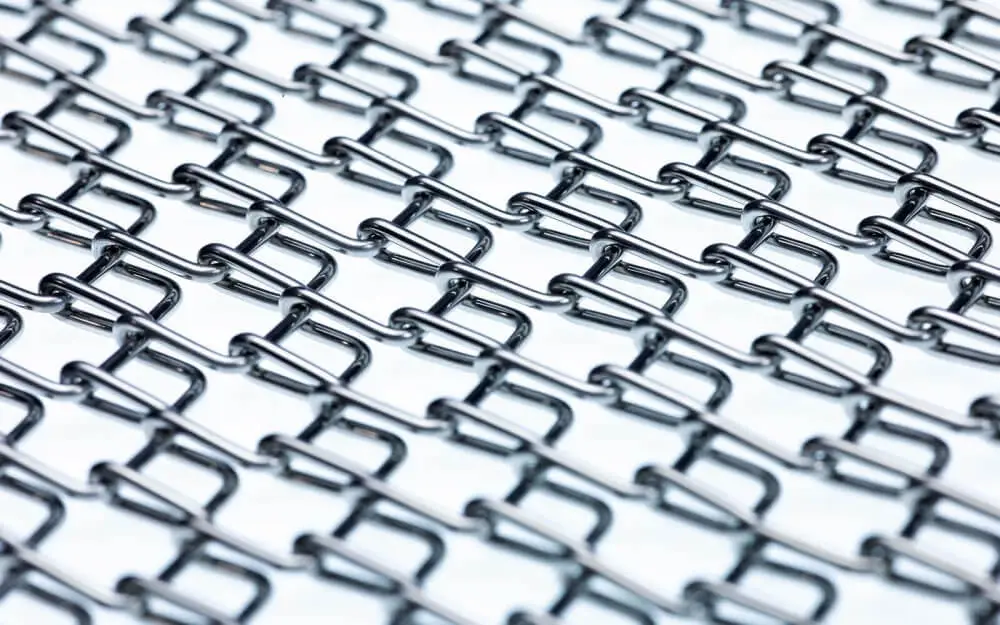

In the food manufacturing industry, keeping a clean, well-oiled production line that complies with strict safety standards is critical. This is where conveyor belts come in; they are in charge of moving goods through several processing phases. Conveyor belts made of stainless steel are currently the material of choice in the food manufacturing sector. Because of their unique qualities and unmatched utility, these belts provide several benefits.

We’ll look at the function of stainless steel conveyor belts in the food industry and talk about the main factors driving their rising demand. Conveyor belts promise to considerably improve the quality and efficiency of food production due to their resistance to corrosion, ease of cleaning, minimal danger of contamination, durability, and wide range of uses.

Conveyor belts’ function in the food manufacturing industry

Corrosion Resistance:

The excellent corrosion resistance of stainless steel conveyor belts is one of its main advantages in the food manufacturing industry. This feature is crucial in settings where belts are subjected to chemicals, moisture, and other potentially corrosive materials, which are frequent in the food processing industry. Let’s dissect the elements that contribute to stainless steel’s resistance to corrosion in order to comprehend this better.

Chromium Content:

When chromium is added to stainless steel, it guarantees the surface production of a passive oxide layer that prevents corrosion of the underlying material.

Appropriate Grades Of Stainless Steel:

Choosing the correct grade of stainless steel can improve its resistance to corrosion under particular conditions, making it ideal for a range of applications in the food processing industry.

Smooth Surfaces:

The absence of deposits that could encourage localised corrosion is one way that polished, smooth stainless steel surfaces increase their corrosion resistance.

Simple Maintenance & Minimal Risk Of Contamination

In the food manufacturing industry, hygiene is crucial, and stainless steel conveyor belts perform exceptionally well in this area. Throughout the production process, their smooth surfaces allow for easy cleaning and sanitisation, guaranteeing the highest levels of hygiene. Conveyor belts made of stainless steel help to preserve food safety and avoid product recalls by lowering the possibility of microbiological contamination. Observing advised installation and maintenance protocols is crucial to maximising the advantages of stainless steel conveyor belts. This includes appropriately fastening belts, lining up machinery, and carrying out routine maintenance and cleaning.

Long Service Life & Durability

Given its reputation for strength and longevity, Flex-Turn conveyor belts are an excellent option for the food processing industry. Because of stainless steel’s inherent strength, the belts can support large loads, take knocks, and tolerate deterioration over time. Because of this, they have a long service life and require fewer belt replacements, which lowers maintenance costs and causes the least amount of production disturbance.

Numerous Uses

Conveyor belts made of stainless steel are ideal for a variety of uses in the food manufacturing sector due to their adaptability. Among the instances are:

- Oven and Baking Belts: Stainless steel conveyor belts are appropriate for baking operations and can tolerate high temperatures, guaranteeing that products pass through the process without adhering to the belt or becoming damaged.

- Belts for Freezing and Cooling: Stainless steel’s thermal durability makes it perfect for freezing and cooling applications, where quick temperature fluctuations might deform or break other materials.

- Processing Meat and Poultry: Stainless steel conveyor belts can withstand impact and abrasion from processing meat and poultry while also resisting chemical reactions, guaranteeing a clean and effective procedure.

- Confectionery and Bakery: Stainless steel belts are perfect for handling sticky or greasy products, like chocolate or pastries, without sacrificing product quality or production efficiency because of their non-stick attributes and ease of cleaning.

In Summary

Conveyor belts made of stainless steel are becoming more and more critical in the food manufacturing industry because of their exceptional resistance to corrosion, ease of cleaning, durability, and adaptability. Food manufacturers can install stainless steel conveyor belt systems to offer a safer, more hygienic, and more productive manufacturing environment. Partner with a reputable conveyor belt solution provider to guarantee the triumph of your stainless steel conveyor belt installation. Their excellent goods, specialised solutions, and all-encompassing support may help you improve the productivity and safety of your food production business.