3D printing is rapidly evolving and revolutionizing the entire manufacturing process. And due to its cheaper and faster prototyping, it’s now gaining even faster acceptance in different fields.

But, one question many people still ask is, “what materials does a 3D printer use?”

We know there are several materials that 3D printers can use, with many of them stronger, cheaper, lighter, and more resistant to temperature than those used for traditional manufacturing processes.

The Process of 3D Printing

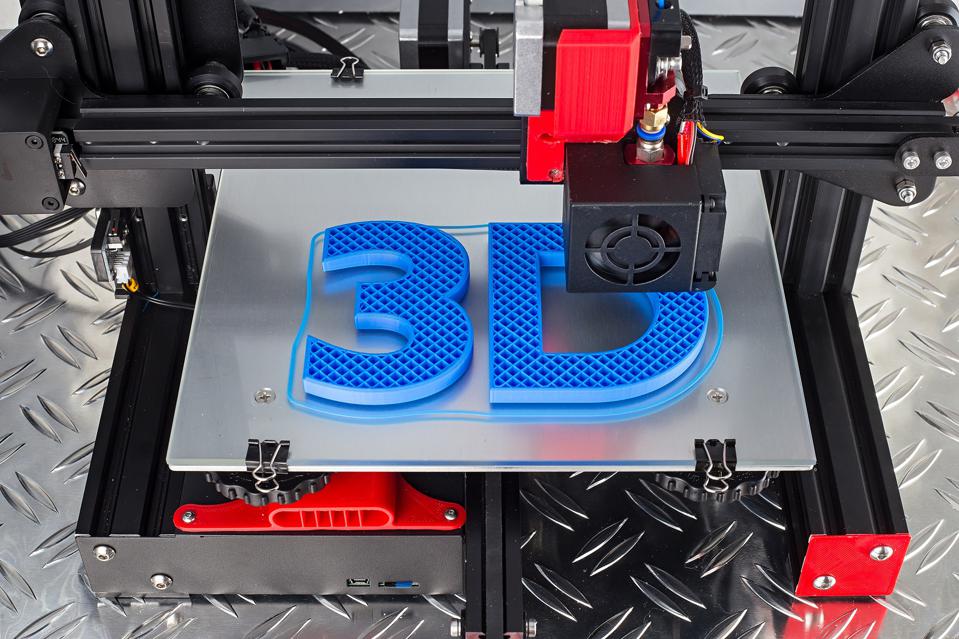

The simplest way to define 3D printing is to describe it as a process that uses models fed into a computer to create three-dimensional objects.

And the process for doing this is described below:

- Modeling: The process of 3D printing begins with modeling. Modeling is the process of turning digital images or geometric data into computer-aided design (CAD) packages. The packages are then saved as files that can be later read and processed using slicers.

- Printing: Once the printable models have been fed into the system, printing begins. The printing involves an additive manufacturing process where the material is melted and stacked layer upon layer until the creation is complete.

- Post Finishing: The post-finishing treatment then ensues once the object is made. This final process varies according to what has been created as well as its intended use. And, while some products need no finishing treatments at all, others require some form of finishing ranging from surface smoothing to treatments with acetone or other solvents.

Common Materials Used in 3D Printing

Below are 4 of the most common materials used in 3D printing:

● Plastics

These are the most common types of raw materials used by 3D printers because of their versatility.

Different types of plastics exist and can be used for manufacturing different kinds of three-dimensional objects. The different types of plastics in 3D printing are Polylactic acid (PLA), Acrylonitrile butadiene styrene (ABS), Polycarbonate (PC), and Polyvinyl Alcohol Plastic (PVA).

These plastics are preferred because they’re firm, smooth, flexible, and come in a variety of colors.

● Metals

These are the second most common raw materials used in 3D printing today and are considered the best when using the Direct Metal Laser Sintering (DMLS) technology.

Metals are attractive because they’re strong and can be used to create solid objects. These objects are mostly used in the aerospace and automotive industries.

Examples of metals that are used in 3D printing are Titanium, Aluminum, Stainless Steel, Bronze, Gold, and Nickel.

● Resins

Many 3D printers utilize resins, but less frequently. They have their limits, but are useful in producing strong objects that must have smooth surfaces with detail.

Some types of commonly used resins include Urethane Methacrylate (UMA 90), Rigid Polyurethane (RPU), Flexible Polyurethane (FPU), Elastomeric Polyurethane (EPU), and VeroWhite and VeroClear resins.

● Powders

The use of powders as raw materials is also becoming popular with the more recent 3D printers. The powders are first melted then carefully distributed to form layers of the object. Printers that use powders do so because they’re easier to control texture, thickness, and patterns.

The most popular powders being used today are Polyamide (Nylon) and Alumide.

Conclusion

There are several types of material 3D printers use in manufacturing objects and preference is usually based on the technology being used as well as the type of objects to be produced.

However, the ones we have listed above are the most common materials 3D printers use.