GC Precision mould Co., Ltd, founded in 2005 by Allen and Thomas, GC mold specializes in providing injection mold China service with USA & Europe quality plastic injection molds to American and European based plastic molders from our China mold company. Because of our advanced mold building capability, we are routinely awarded builds that would normally, not be considered for off-shore sourcing.

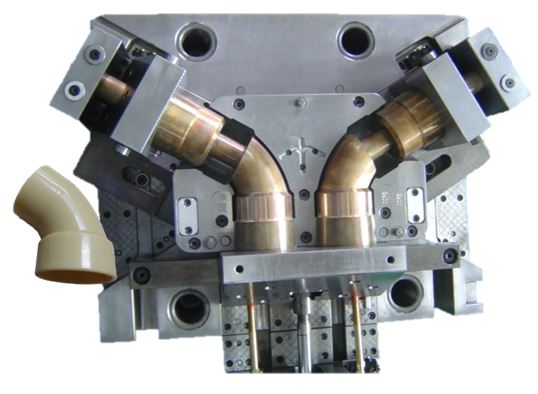

GC MOLD has experience building, stack molds, laminated molds, clear injection molds, reflector molds, multi cavity molds, over molds, two shot molds, multiple slide molds, large family molds, and molds that weigh up to 25 tons. We routinely build injection molds for Automotive, medical, industrial, food package, digital, electronic, consumer and OEM products. We have the ability and resources to complete multiple mold builds on schedule. We are ISO 9001:2008 certified and provide complete mold services from part design, mold design mold manufacturing, injection molding production, assembly and secondary process. All of our injection molds are guaranteed to operate correctly and trouble free. All of our molds are supplied with steel certification, heat treatment certification, molding parameter report and part dimension inspection report, 100% dimension meet to customers 2Ddrawing. We are not one of those China mold companies that slap together a mold by drilling 4 holes in the A plate and then wire out the opening, then drop in the insert and use a thin backing plate for the insert so we can save dollar worth of labor on a 35 day build. We do it the old fashioned way. Blind pocket, hand fit inserts on all our injection molds.

Mold STANDARDS & MATERIALS:

Parting line interlocks, a cycle counter and pry bar slots that you see on all the molds from injection mold China companies that are exported to the overseas customers look great on the outside but don’t not sure the standard of the components, the mold standard component in all of our export injection molds are made according to DME, HASCO standards, or according to our customer requirement. DME & HASCO standard that means, leader pins, guiding bushings, ejector pins and all other components that can be easily serviced or replaced at our customers side, of course if the molds are in the warranty time, any components or inserts have issue we will make free inserts and components for our customer. Mold base and insert steels for the export molds are normally 1.2344, 1.2083, H13, 1.2738H, 1.2343, S136, NAK 80, all of steel are selected by our customers based on application. USA, German, Swedish, Japanese, and of course China steels, are routinely supplied to our customers,

As a result of customer demand we have a professional Engineering team to support our customer, to avoid any language communication problem, all of our engineers are specking good English and have over 7 years of working experience in the mold field, most of them were mold maker and mold design in their past jobs background. Base on their professional technical and good English skill, all of our customer are taking care by our team.

As a professional China mold company, we offer injection molding service as well, If you want us to build molds and produce the molding parts for you, we have 20 sets of injection molding machines to support you well, we have wide range of tonnage injection machines from 80tons to 1600 tons, three of them are two color paralleled injection molding machine, some of our injection machine are specially for PMMA or PC clear injection molding parts, we can produce wide range of plastics, such as PP, ABS, PC, PMMA, PS, PA66, PA66 GF, POM, TPE, PET, TPU, PPS, etc.

Our 17 years of experience can be serve our customers better and better all the time by continuous research and development and adopting customers’ feed-back and needs, because GC mold wants to provide user-friendly, high precision and highly productive injection molds from our China mold Company.