Industrial robots are systems that are deployed for manufacturing. It is automatically controlled, reprogrammable, that can be equipped with multifunctional probes. The mechanical devices are used instead of a person in order to complete tasks that are less exciting – in other words, repetitive. The world of robotics is made up of intricate systems. When contemplating robots, you immediately think of the much-loved droids from Star Wars. At present, robots have incredible potential, carrying for all sorts of routine and complex tasks. They exist to assist humans and not to replace them. With better computers, as well as artificial intelligence, bots will be able to evolve to a new type of intelligence. Until that happens, it is a good thing that there are millions of industrial robots in operation all over the world.

It is very important to choose the right robotic arm to handle a job on the production line. While some jobs require bigger robots, which ensure stability and reach, others necessitate small industrial robots for tasks like enveloping. It is difficult to position and manipulate in confined spaces with limited entry. The only ones that are capable of carrying out specific processes are small robot arms. These compact and precise machines are absolutely necessary when it comes down to assembly and manufacturing automation. Attention needs to be paid to the fact that there are several types of small industrial robots. Getting a good understanding of each type is essential when selecting a good fit.

The different types of robotics and applications

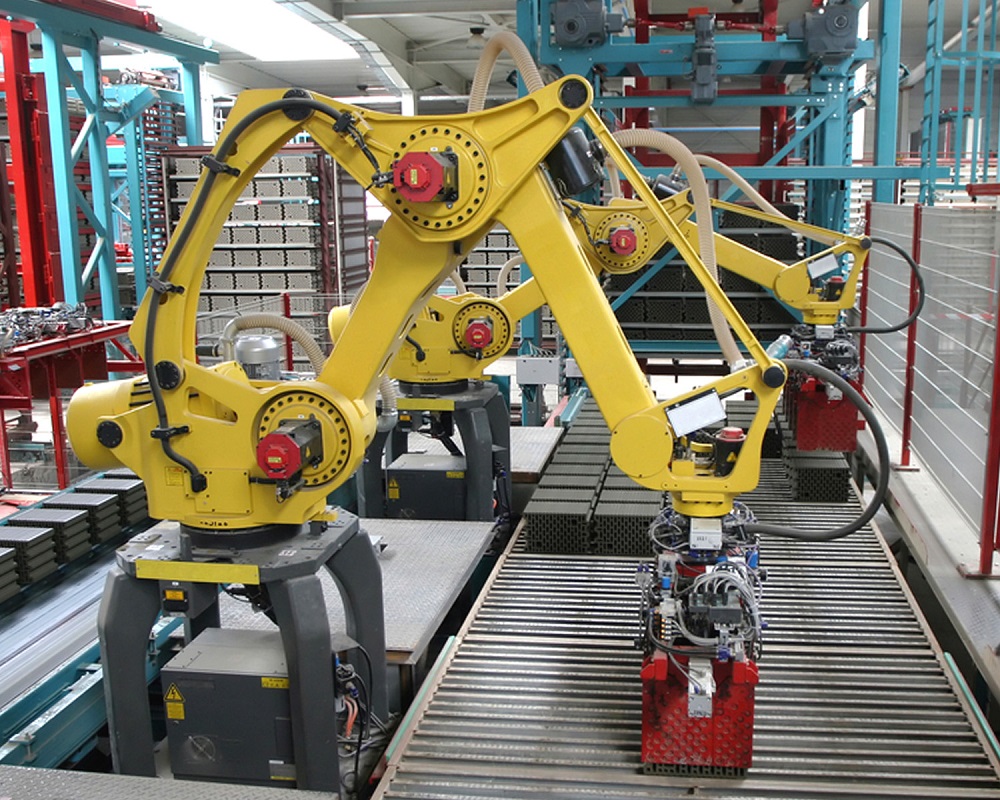

Robots make life easier and safer. They are so smart that they can make progress in factories and laboratories. Automation is not only inevitable but also desirable. With a small industrial robot, you can make changes in the organization and lead the way to innovation. A bot can be utilized to automate tasks involving repetition like picking up objects. For the time being, small robots are used exclusively in the industry. There is no way of knowing when they will be accessible to everyone. What is sure is that people will not have to wait long. The machines can be classified according to their applications. In addition to that, systems like SLC 500 have made the lives of engineers much easier and the process of manufacturing much smoother. Small industrial robots are available for various applications, such as:

- Assembling

- Welding

- Painting

- Palletizing

- Material handling

Models are created for specific labor-intensive processes, digitizing operations and increasing productivity with minimal changes. The aforementioned actions would normally be undertaken by humans. Thanks to automation and mechanization, factory workers work fewer hours a week, not to mention that they are protected against the hazard of the environment. Each application has different physical and functional needs. For instance,paint robots demand small payloads for the jobs at hand, in addition to large movement. It is interesting to note that robotic systems can be configured for several types of tasks.

Description of the robot movement

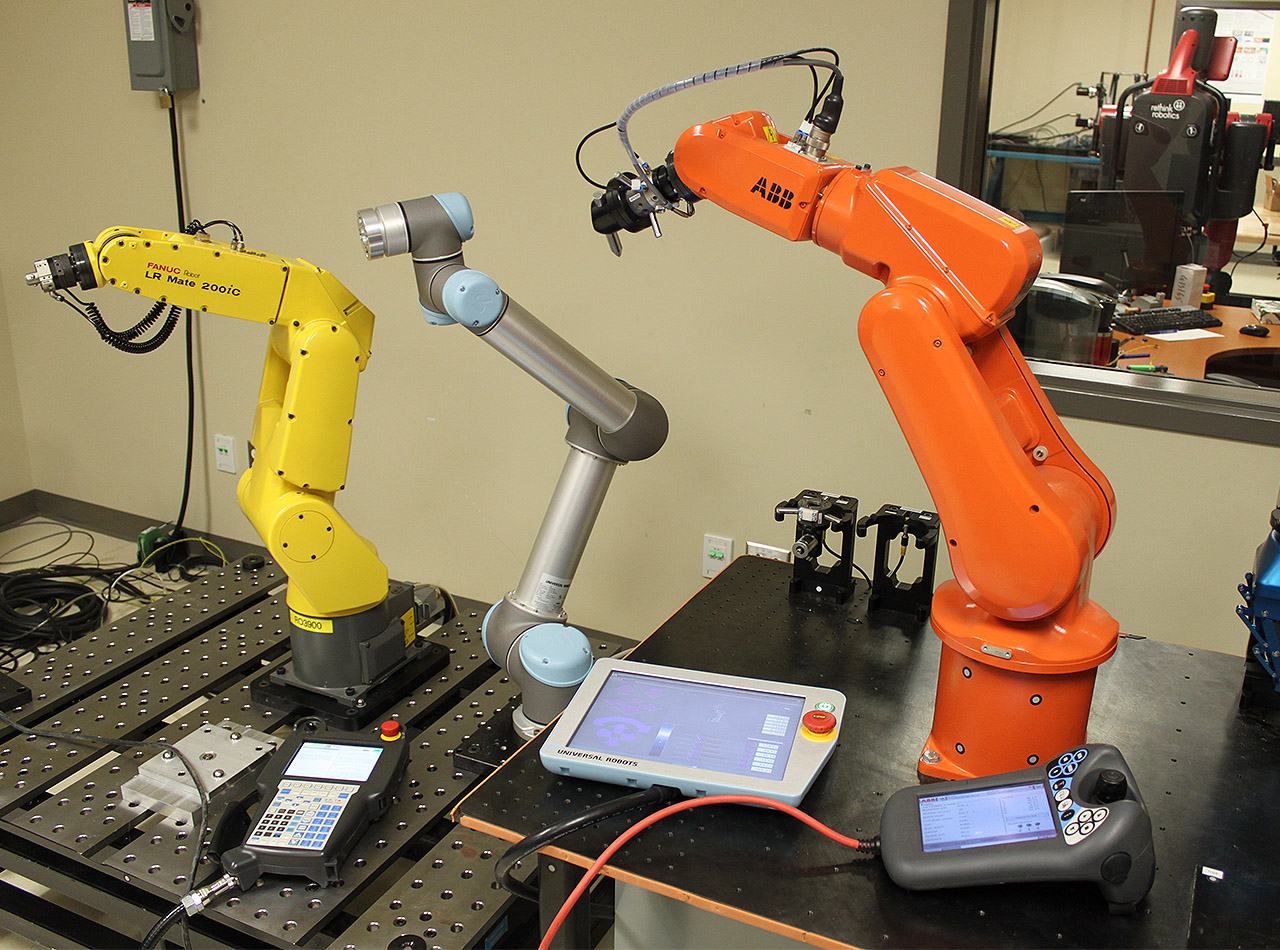

The one thing that bots have in common is the fact that they have a movable body. This means that they have the ability to move in the same way as humans. Small industrial robots are designed with expressive movement in mind. The aim is to deploy robots in more contexts. Some bots have more flexibility than others. Here are only a few examples of small industrial robots that boost output, productivity, and efficiency:

- Robotic arm: This is the most prevalent type of manufacturing robot. A robotic arm is basically a type of mechanical arm that has almost identical functions to the human arm. It is available as a 5 or 6 axis robot for positioning and orientation. Robotic arms are recommendable for complex applications where fine movements are required. It is possible to equip the robotic arm with numerous effectors that are suitable for a specific application.

- Cartesian: By Cartesian, it should not be understood a follower of Descartes, but a robot that uses linear slides. As opposed to other multi-axis systems, Cartesian robots perform coordinated motion and simplify the robot control arm solution. They are not deployed only for injection molding

- Dual–arm robots: Certain types of small industrial robots can carry out tasks by recognizing objects, taking decisions, and modifying the amount of force applied. Dual-arm collaborative robots are successfully used in industrial applications, ensuring benefits such as flexibility, two-hand operations, cycle time enhancement and so on and so forth.The programming approach involves both online and offline methods.

Picking and purchasing your first small industrial robot

This is the age of robotics. Companies are already making tool changers and grippers for smaller robots. The industry keeps on growing and manufacturers ought to take advantage of today’s innovations. There is a small industrial robot for every task. It is important to take into consideration the process in the manufacturing environment that you want to improve. This involves being specific as far as the issue is concerned. Take into account the following factors when it comes down to your robotic automation project:

- Adaptability: Bots can work together with human workers, as long as they are equipped with spatial awareness.

- Intelligence: With high sensing abilities, small industrial robots can complete complex tasks and even give feedback.

- Work cell: The manufacturing environment should be designed to accommodate the robot. Robot integrators assess your system needs and offer a plan for automation. Adjustments can be made ahead of time, guaranteeing that the bots are sized for speed and reach.

You are not an experienced mechanical, electrical engineer, so it makes sense that you do not know what type of robot to select. If you have any questions or inquiries, it is best to speak to the automation designers from the company where you are planning to acquire a small industrial robot. If you still do not know what to choose, direct your attention towards collaborative robots. They meet all safety standards and do not have to be taken out of the way of employees. What is more, they do not necessitate programming. The choice of collaborative robots is application dependent. That is something to keep in mind.